Western Shipping Safety Seminar – 28th & 29th Jul 2020 – Online Webinar

MID YEAR SAFETY SEMINAR 2020 – Webinar

Due to current COVID-19 Pandemic Situation, the safety seminar this year will be online webinar through ZOOM.

Venue: Zoom – WSP Conference Room

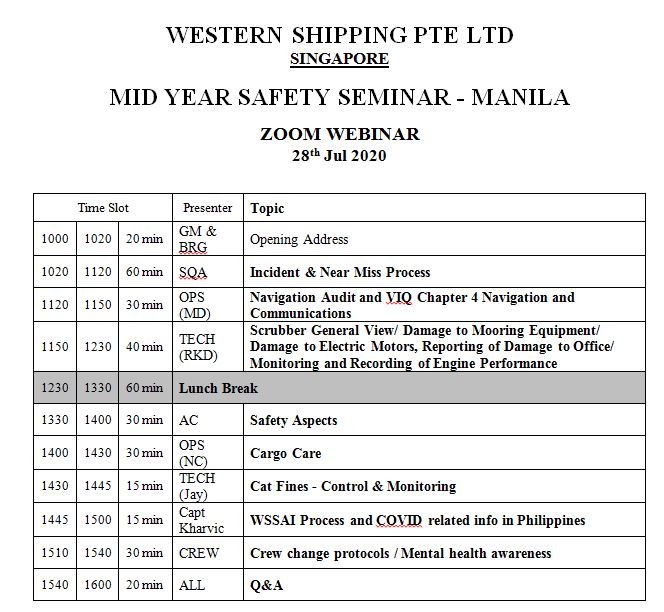

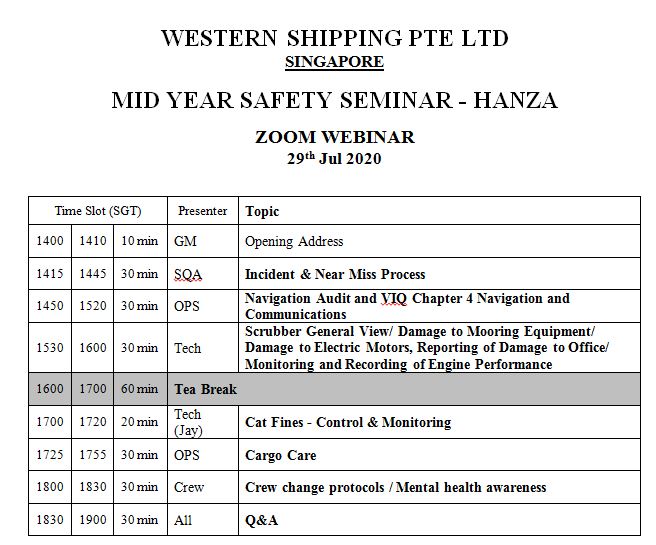

Date: 28th Jul 2020 for Manila and 29th Jul 2020 for Riga

Slogan: Safety during the Covid-19 pandemic

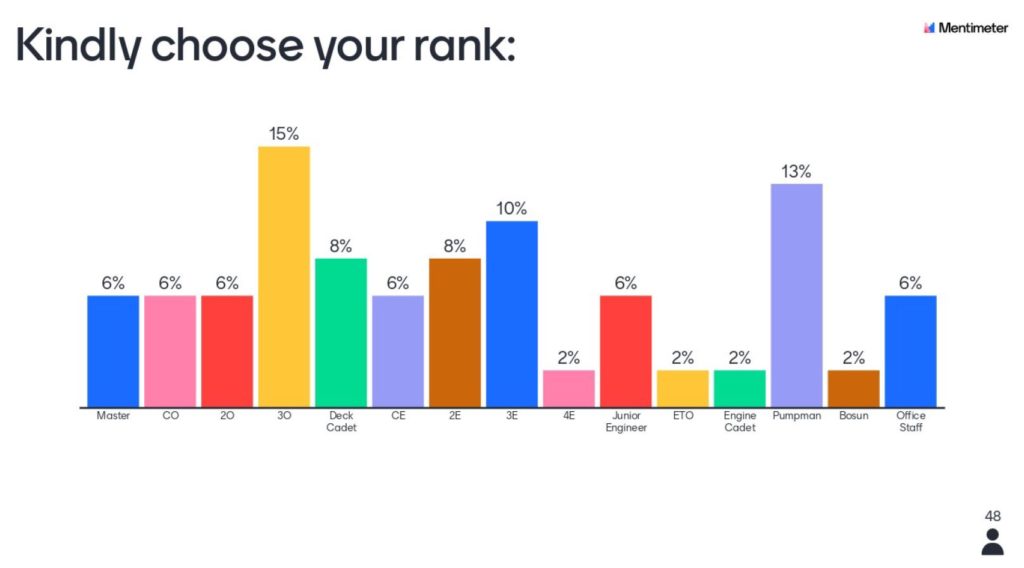

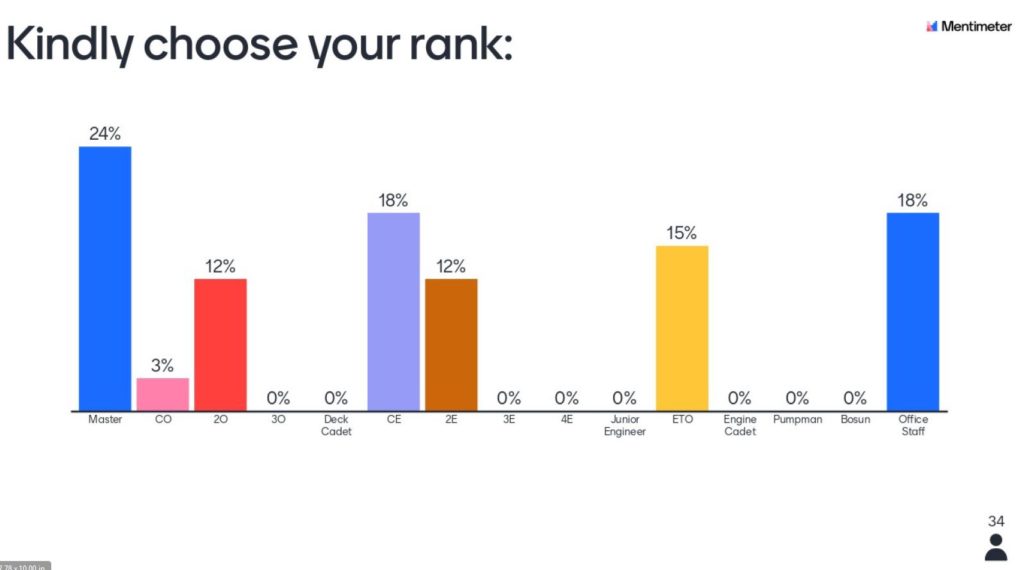

Attendees

Invitation was extended to all officers working in Western Shipping fleet. All seafarers attended the webinar via zoom call. WSP staff attended through zoom call at the Singapore WSP conference room. Manila staff attended through zoom call at the Manila Bridge Simulator room. Riga staff attended through Hanza Office.

The seminar was organized for seafarers working on our tankers. The topics were introduced as necessary, with specific emphasis on safety matters and recent updates within the fleet. This enabled targeted presentations relevant to the vessels being served. This was the first time that, in addition to all officers, invitation was also extended to Bosun and Pump-Man within the tanker fleet

Western Shipping Pte Ltd (WSP) was represented by:

- Capt Belal Ahmed / General Manager

- Panos Zavlagas / Deputy General Manager

- Capt Hemant Arora / SQA Manager

- Capt Rukshan Vohra / Fleet Personnel Manager

- Capt Niladri Chakraborty/ Operations Manager – Marine

- Capt Mohan Dhinakaran/ Marine Superintendent

- Ravi Kant Dwivedi/ Assistant Technical Manager

Western Shipping Southeast Asia Inc (WSSI) was represented by:

- Adm Bayani Gaerlan / President

- Capt Kharvic June L. Sitchon / General Manager

- Jay Esguerra / Technical Superintendent

Western Shipping Manila Taining Centre (WSPMTC) was represented by:

- Capt Alban Castellino / Consultant

Curriculum

The Seminar was opened by General Manager, Capt. Belal Ahmed. Topics later discussed were as per the above agenda. All participants submitted their queries using the chat function of Zoom. A summary of all questions was made, and responses provided at the end of the seminar.

Q&A

Q: For Capt. Niladri: Ref to maintaining seal rings and hydraulic valves actuator seal kit spares onboard, It is common knowledge that procurement of such spares can be lengthy plus they are subject to a certain shelf life / expiration. Kindly offer your advice on this issue please.

A:It is well known that seat rings have shelf life, even after storing in cool dry place. However, as the vessels are ageing and original makers usually have a very long lead time for supply, we have no alternative. We need to procure from open market and we also need to maintain some spares on board to rapidly address a failure. The quantity of spares to maintain is already prepared, which is experience based.

Q: For Capt. Niladri: Seat ring renewal every 5 yrs for original but supply onboard was fabricated it very often to break down only few operations will get damage.

A:Though there is no fixed interval for seat ring, but experience has shown that original seat rings lasts more than 5 years. Failure of seat ring is not only about quality, also how it was installed and presence of debris within the line. Due to difficulty in procuring from maker, we have procured from other vendors. We have identified that supply from one of the vendor is failing within a short interval, now we have changed the supplier and also brought about some improvement. We cannot ensure durability but continuously assessing information to determine expected lifespan of seatrings from different vendors. We hope future supplies will perform better.

Q: For Capt. Niladri: Please advice on regarding keeping sufficient stock at all times versus spare expiration.

A:In absence of data, we have decided that 25% of the total requirement, should be a reasonable number to maintain as spare. Anyway, as we gain more experience, we may change this figure again.

Q: For Capt. Unni/Niladri: Hydraulic changes and testing of oil requirements

A: Testing of Hydraulic oil for all systems is 3 months. Every 3 months the Hydraulic oil sample to be landed for analysis to respective testing company. If there is any warning noted in the analysis, the technical Superintendent will advise the action to be taken. Hydraulic oil for Cargo valve should be renewed every 5 years. The sludge accumulated in the sump should be cleaned. The filter in the power pack should be maintained as required in the PMS system.

Q: For Capt. Rukshan: what are the protocols implemented by the company to ensure the safety of its crew against COVID-19?

A: PPE for joining & signing off. Office will provide. Signing off – Master should be fully aware to provide basis COVID

Q: For Capt. Rukshan: How is the future of crew change?

A: Wherever possible, we continue to engage in crew change activities. Due to new requirements being put in place at very short notice by different countries, the situation is fluid and ever changing.

Q: For Capt. Casty: Please advise us on the lead of new industry requirement of the upcoming Risk Matrix which introduces “Detectability”.

A: Detectability if formally used will be plotted on the “Z” axis, to Calculate Risk Priority number. Using Detectability we can reduce both the “severity potential” as well as the “potential of probability” We already use Detectability informally and is manifested by “technical means” (e.g., Detectors & Alarms in Systems) as well as “human means” (actions to take on detection) Unfortunately, once again the “gap-factor” is the human’s due diligence in maintaining the detectors and correctness of response to the alarm generated. Hence Detectability will move us ahead on the Management of Risks, but will ultimately be hinged on the Human-Factors.

Q: For Capt. Casty: Understand detectability (though not expressed) indirectly helps/assist a person to asses to list down the hazard and grade the severity and likelihood.

A:By understanding how we can effectively incorporate “Detectability” into our Risk Management Processes, we can diligently pursue the induction of “detection & reaction” into our Thought-Processes, whenever we conduct a Risk Analysis, and continue on to the Risk-Assessment, and evolve into the risk Management Process.

Q: For Ravi: Can you share the EGC system thru DVD disc and all some other topic

A: Material used for Webinar will be shared with all attendees and fleet vessels. Also FYI each vessel has got manual on board which are in soft copies and must be read to understand operation and maintenance requirement of EGCS.

Q: For Ravi: now that almost of the ship have EGC System how much kw load will add to A/E.

A: In WSPL oil tanker fleet we have 5 vessels which are/will be with EGCS. Rest other vessels are using 0.5% S VLSFO. Ship with EGCS has scrubber pumps which are load dependent so the system is designed to run with 2 A/E. S.W scrubber Pump speed changes to increase/decrease the disch capacity based on engine load. Sea Load increase with EGCS will be say about 250KW.

Q: For Jay: Follow up Question, How this Cat fine affects the engine?

A: On liner side. Abnormal wear on cylinder liner & piston rings. Unscheduled Maintenance will be required.

Q: For Jay: Can we use two or more filter instead of one filter so that cat fine cannot penetrate to go thru the engine?

A: Depends on size of filter. At least 10-15 microns. Engine maker specifies the same.

Q: For Capt. Kharvic: how are the process for those who are not able to go to the company medical hospital (physicians hospital) due to a local lockdown and quarantine checkpoints and curfew

A: Company will provide a letter an Employer Letter stating that crew is an essential worker in addition to LGU’s travel pass. We are currently in the process to accredit additional PEME Clinics all over the Country. At the moment we are very fortunate that aside from MANILA we also have accredited PEME clinics in CEBU, ILOILO,DAVAO, CDO.

Q: For Capt. Kharvic: We appreciate your great job during this trying times, my question is, lately there are a news that COVID -19 Contamination are mostly like happens during Medical Examination(PEME) in clinics, Is it possible that if seafarers Medical Certificate is still valid with more than his next contact be accepted/extended without taking another PEME to avoid Covid -19 Contamination.

A: There is no evidence to support where the risk of infection is more. In general, a person may get infected at any place where there is a congregation of people. In general, the requirement for PEME prior joining will remain. Case by case waivers may be considered depending on circumstances, when last PEME was done and seafarer’ previous medical history.

Q: For Capt. Kharvic: It was a nice presentation now my question is since the Marina Memorandum/Circ. with regards to renewal of COC does it covered COC’s that will be expiring this coming October 2020. As what I understand it is until July 31 only. Would appreciate if you can give me more clarification with regards to this?

A: COC’s with validity up to 31 July 2020 is extended until 6mos, this is applicable for crew who are currently onboard.

Q: For Capt. Mohan: How soon will electronic documentations be introduced on ships?

A: New Vsl already started with electronic publication. Discussion in progress within the Management for entire Fleet to change to electronic. In addition, PMS in ABS NS. End of 2020 for the Fleet for implementation.

Q: For Capt. Mohan: During transit of Singapore Strait we must have Bridge Level 3. What should we do if we will not comply for work and rest hours regulation?

A: Before transit, Take sufficient rest; During transit, Master to handover conn depending upon situation; After Transit, Post compensatory rest. Critical is not complete OFB till Horsburg – Needs to be well planned by delegating C/Off. Bridge – 4 Off & 3 AB 2 OS – Depending upon arrival timings, stop other maintenance work 1 day prior so that all crew have rested. Master – Will be required at Critical stages and Master MUST be available on Bridge, but C/Off can take over in non-critical areas depending upon location traffic etc. Engine Room to be manned, proper planning well in advance, Risk Assessment. Vessel calling Singapore Port – If Master & officers are fatigue, Master to approach Office for compensatory rest and vessel sailing will be deferred till adequate rest.

Q: For Capt. Rukshan: Does the company plan compensation payments for seafarers who are on shore for a long time due to COVID-19? Please also advise do you have plan (due to COVID-19) to pay additional salary to crew onboard, who could not be changed after complete contract?

A: WESTSHIP has quite managed policy, so it is not possible to make any blanket policy. There have been few cases depending upon situation where Company do consider for seafarers especially where the seafarer wages are not high especially ratings, Wages have been approved. If any seafarer has financial commitment, Pls approach company and will be happy to assist.

Q: For Capt. Rukshan: Please advise where do you plan crew change for Arizona Lady?

A: Depending upon location, but will try the best.

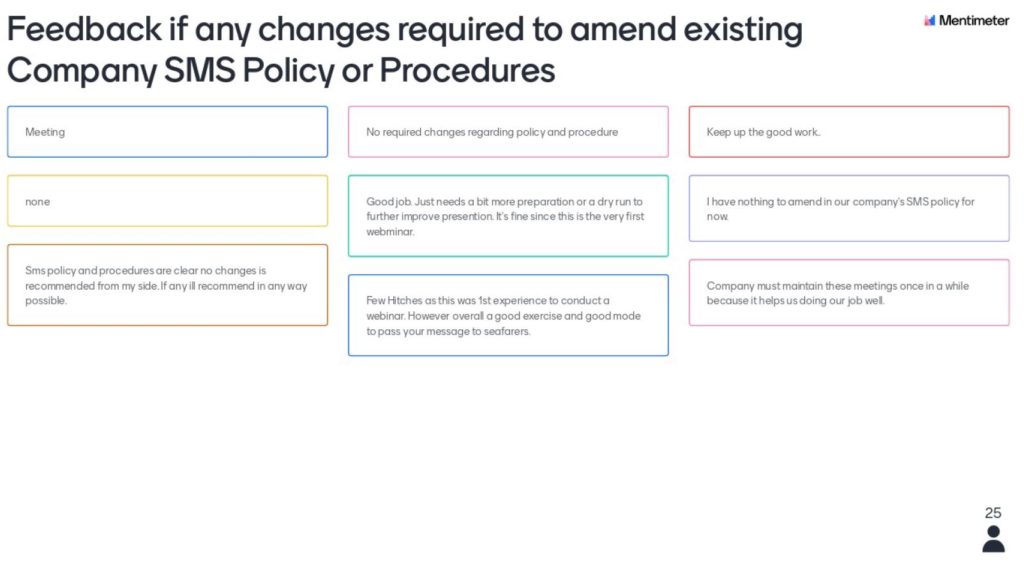

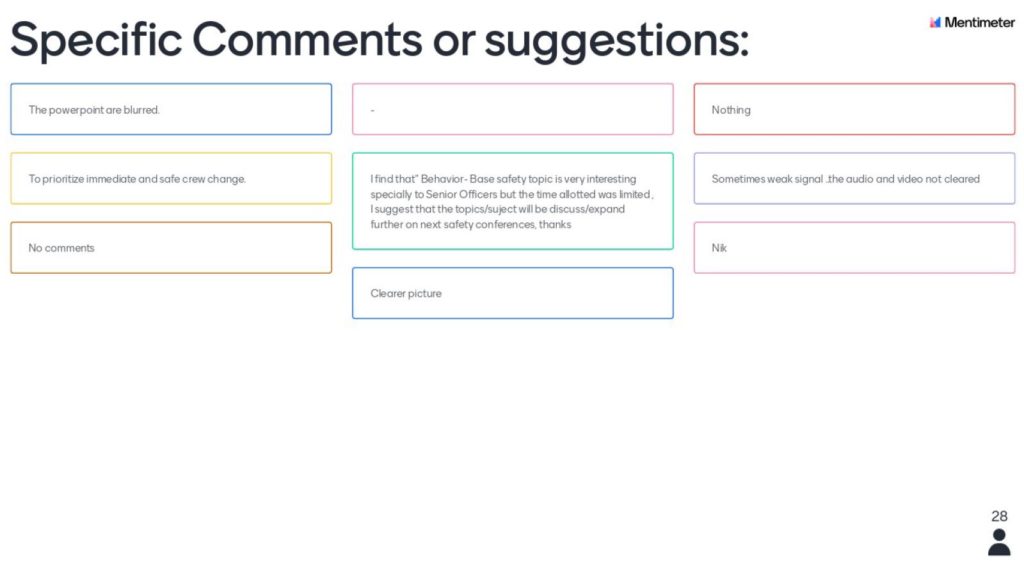

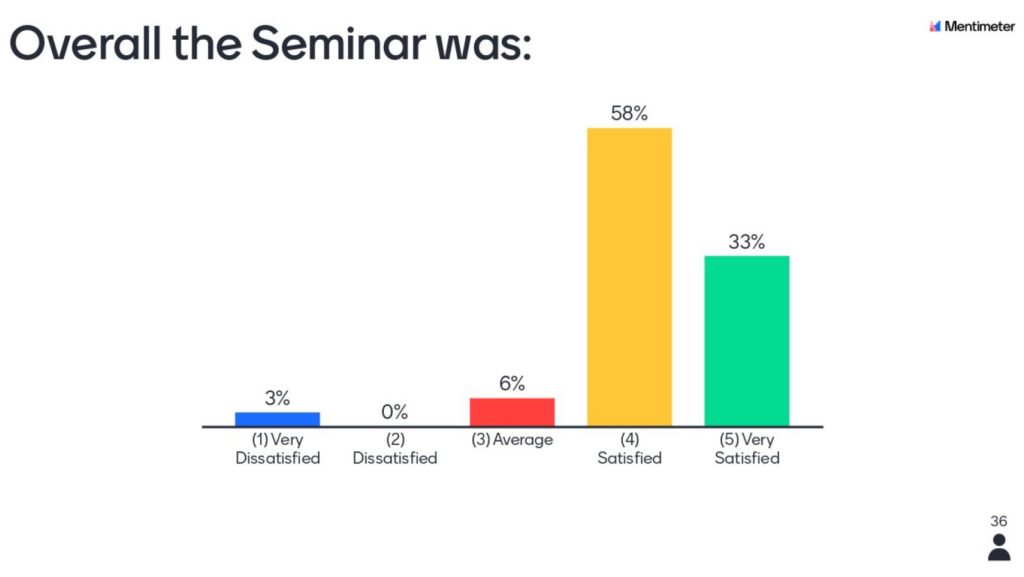

Feedback

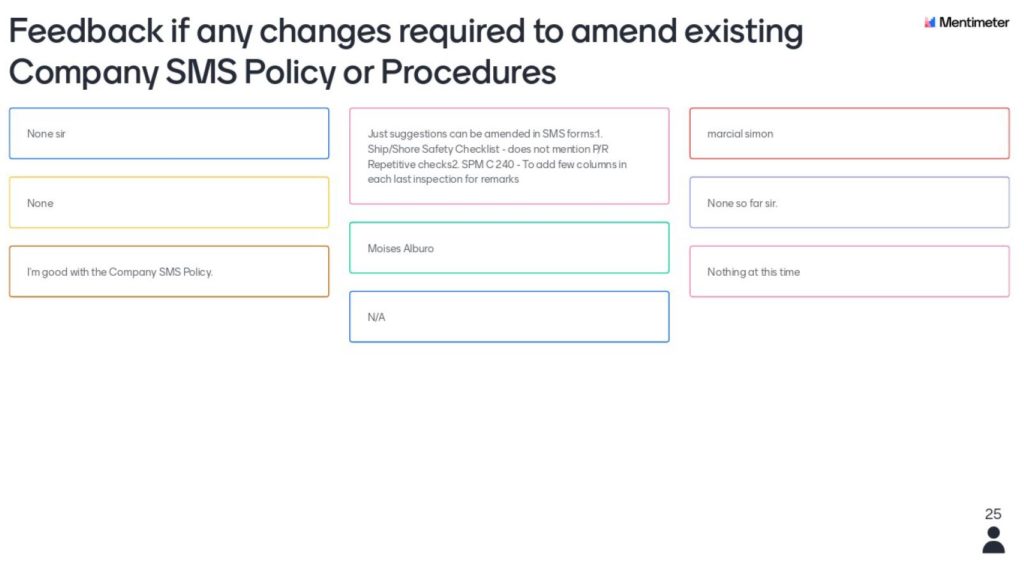

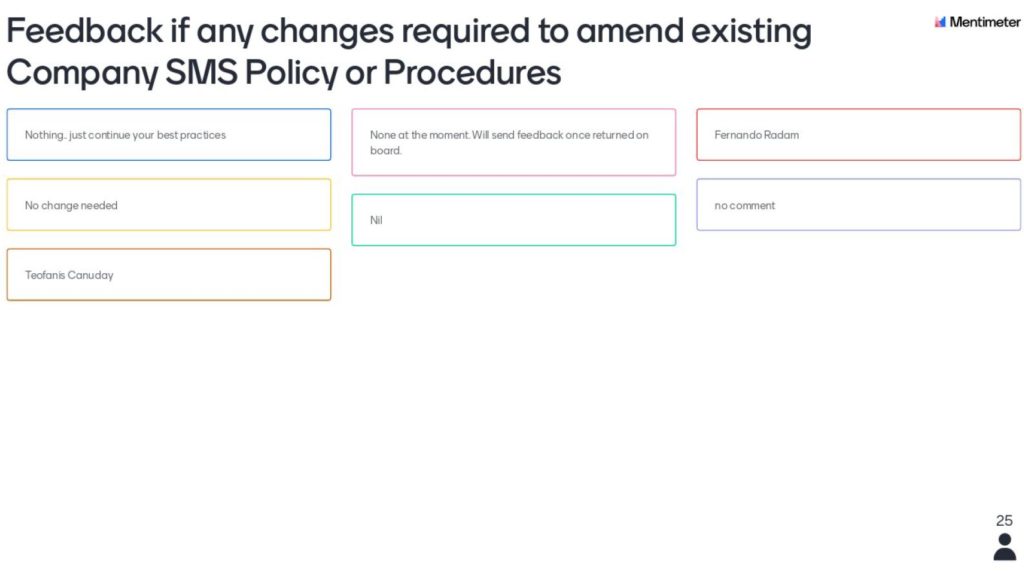

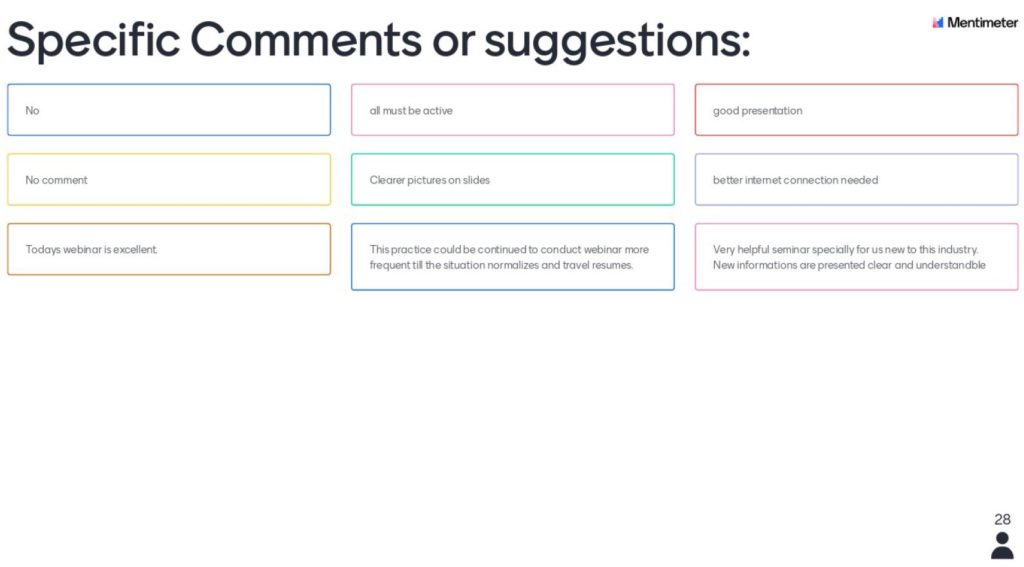

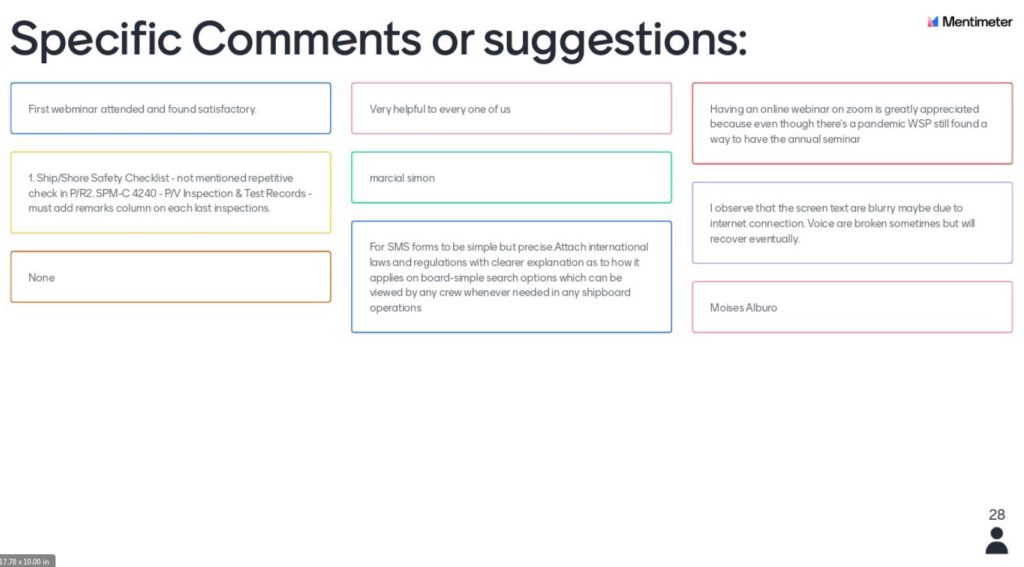

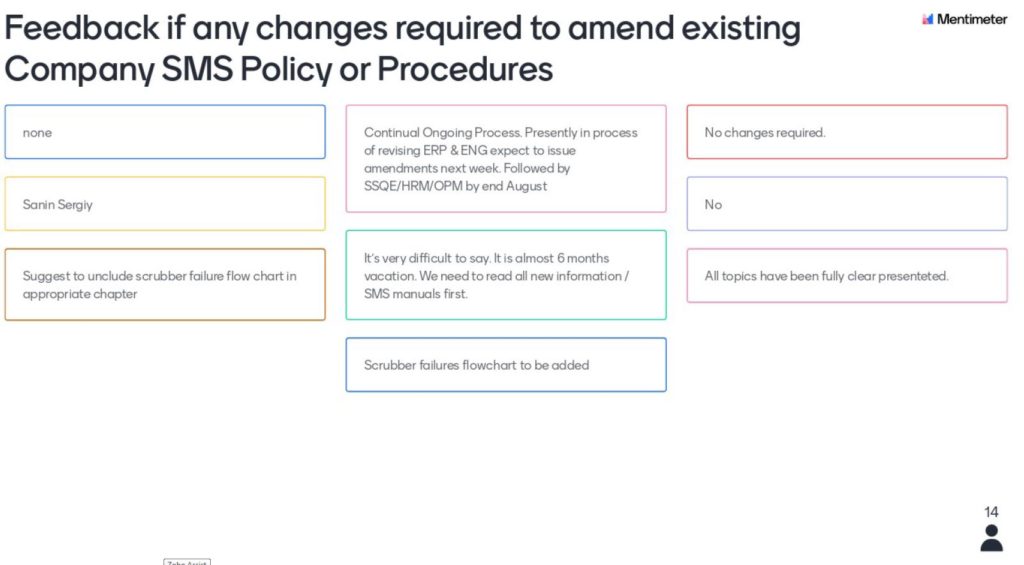

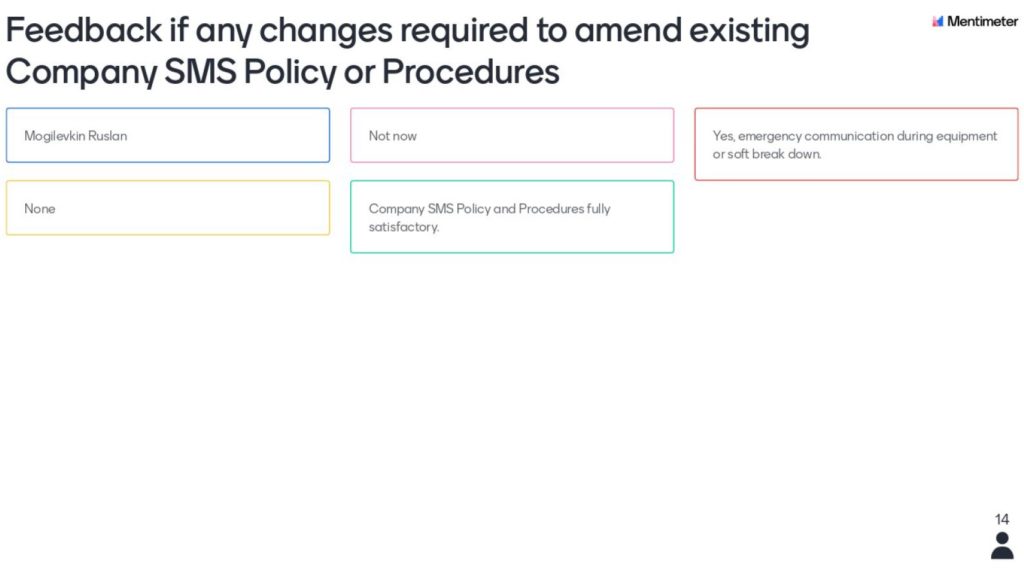

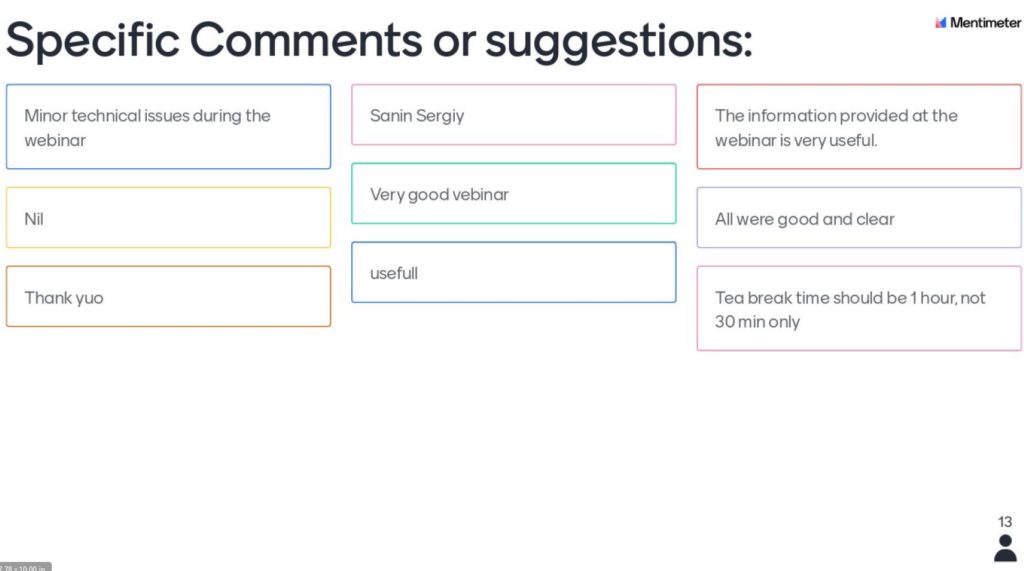

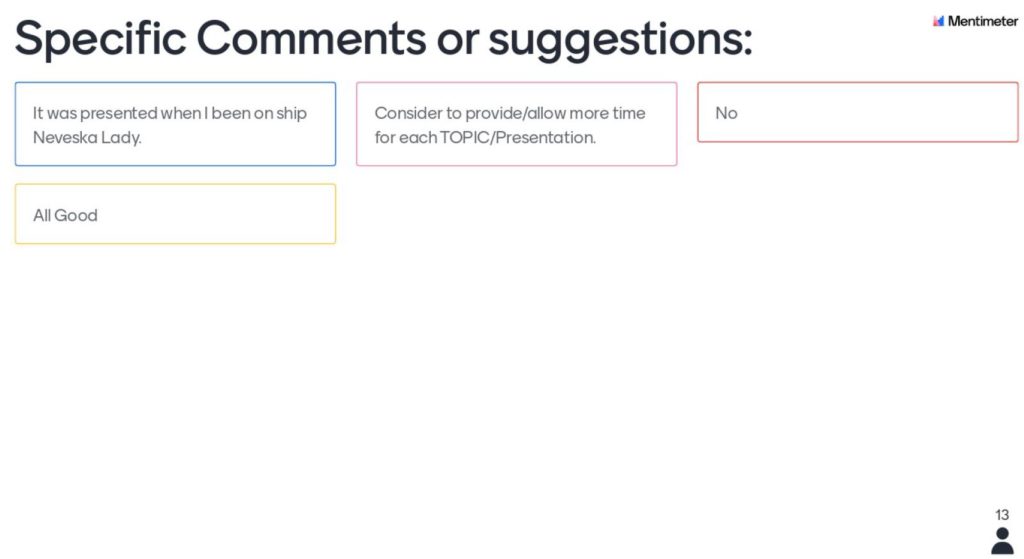

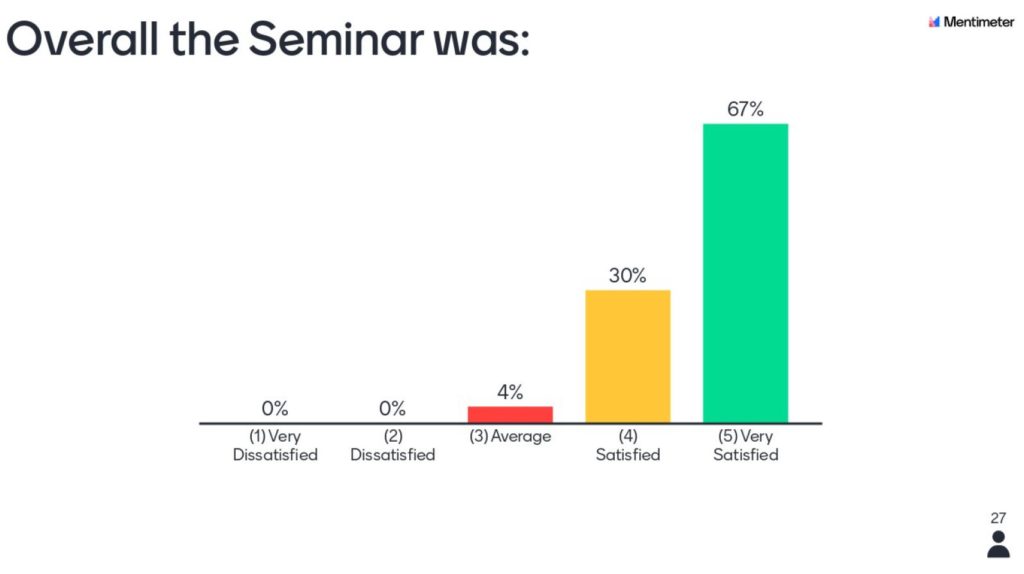

Feedback was collected from all attendees and collated using the application MentiMeter in order to incorporate improvements next year.

Feedback on 28th Jul 2020

Feedback on 29th Jul 2020

General feedback received indicated the seminar to be a success. All arrangements made were appreciated. Punctuality was maintained throughout the seminar by the attendees.