Health, Safety and Environment Bulletin Jun 2019

Poor Lookout Led to Collision of Fishing Vessel with Tanker

The incident

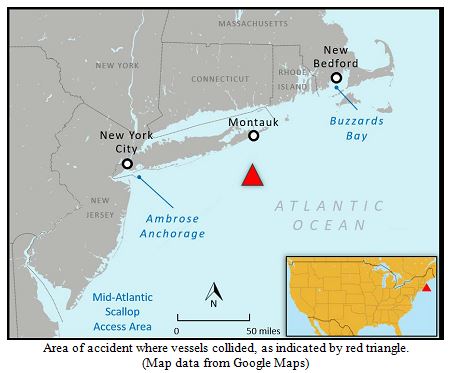

On 12 May 2018, about 1913 local time, the fishing vessel Polaris transiting with a crew of 7 and the tanker ‘Tofteviken’ with a crew of 25 collided about 30 miles south of Montauk, Long Island, New York, during daylight and good visibility.

There were no reports of pollution or injuries. Both vessels sustained hull damage amounting to $716,047.

Probable cause

The National Transportation Safety Board determines that the probable cause of the collision between the fishing vessel Polaris and the tanker Tofteviken was the failure to maintain a proper lookout by the mate on the fishing vessel and the failure to identify the risk of collision by the third mate on the tanker.

Findings

Maintaining a proper lookout, by sight and sound, is a fundamental rule of the COLREGS for vessels on the high seas, regardless of their size or activity. Yet, the Polaris mate on watch was occupied with a cleaning task in the pilothouse. He therefore did not keep a proper lookout or notice any danger or risk of collision until he heard the port paravane making contact with the hull of the Tofteviken.

The captain of the Polaris confirmed that it was routine to clean the pilothouse on the return trip to port to avoid having to clean the vessel once it was alongside and thereby delaying the crew from immediately disembarking the vessel. The mate stated that occasionally he would leave the pilothouse unattended, which was not uncommon during his watch.

“This practice, accepted by the captain as well as by the company, did not promote effective watchkeeping and distracted the mate from maintaining a proper lookout.”

Further, although the mate on the Polaris had radar available, he was checking it at infrequent intervals and without the use of long-range scanning, which, collectively, could have alerted him to the developing collision course with the tanker.

The third mate on the Tofteviken did not use all available means to determine the risk of collision, the investigation found.

Although she identified the fishing vessel visually and by radar at a distance of about 8 miles, she did not adhere to company policy that required her to utilize the ARPA and radar guard rings for acquiring contacts.

Instead, she only placed an EBL on the Polaris’ radar target; however, investigators found no evidence that she monitored the progress of the vessel in relation to the EBL.

Furthermore, the third mate did not follow the master’s standing orders and company policy that required her to notify the master, who was on the bridge at the time, of the Tofteviken’s proximity to the Polaris.

The master was only alerted to the fishing vessel’s proximity by the chief engineer, who upon arriving on the bridge instantly recognized the dangerous situation that had developed. Once the master realized that the collision was imminent, he took action to avoid the collision, but it was too late.

“When making assessments or predictions about a situation, there can be a tendency to rely more heavily on information that reinforces one’s expectations and avoid information that may contradict those expectations. This concept is called confirmation bias.”

In this case, the third mate on the Tofteviken expected the Polaris was going to pass astern of them. To bolster her confidence of this expectation, the AB shared that he too believed the vessel would pass astern.

“Having her expectation reinforced could explain why she did not utilize the functions of the ARPA or monitor the relative motion of the Polaris as it was approaching. However, had she followed the master’s standing orders, this accident could have been avoided.”

Lessons learned

-Proper lookout

Non-navigational routines should never interfere with the primary task of a watchstander or a bridge team member to maintain a proper lookout. Should performance of another task or duty be necessary, an extra lookout should be posted.

-Early communication

Early communication can be an effective measure in averting close quarters situations. The use of VHF radio can help to dispel assumptions and provide operators with the information needed to better assess each vessel’s intentions.

On the Tofteviken, the third mate did not identify that there was a risk of collision because, based on her observation that the fishing vessel seemed to have altered course to starboard, she expected that the Polaris would pass astern.

(Source: US National Transportation Safety Board)

NOTE: VHF communication to avoid collision is not recommended by WESTSHIP, rather COLREGS must be adhered to.

Practical Challenges With Open Loop Scrubbers

What is an open loop scrubber and how does it work?

The open loop design, referred to as seawater scrubbing, uses seawater to scrub the exhaust gases before discharging the washwater back into the sea following treatment. As the sulphur dioxide is removed and dissolved, the remnant of the treatment produces an acidic effluent. It is the natural alkalinity of the seawater that is used to neutralise this acidity. A small amount of sludge will also remain on the vessel.

Considerations when using or opting to use the open loop system:

- Efficiency depends on water alkalinity. The efficiency of the scrubber process increases with higher alkalinity. Lower alkalinity implies a higher need for wash water and results in higher energy consumption, thus the vessel’s trading area needs to be considered.

- Some ports in the US and Europe prohibit the discharge of the washwater.

- Open loop systems enjoy lower OPEX than closed-loop/ hybrid systems and also benefit from a lower installation footprint than closed-loop/hybrid systems.

An aspect that most certainly has to be considered by shipowners with an open loop system is what their Flag, Class and USCG requirements are, the need for an IAPP certificate, SECC (SOx Emissions Compliance Certificate), OMM (Onboard Monitoring Manual) and EGC-SOx notation (optional). Shipowners should also be aware that it is likely that checks will not only be made on the initial emission performance but rather, given the sensitivity of the particular topic in terms of environmental concerns, there is likely to be continuous monitoring of operating parameters and exhaust emissions.

There must also be a planned inspection and maintenance procedure. The crew will need to be fully trained in the operation of the open loop scrubber and the need to maintain records of its use and maintenance vigilantly.

The primary concern for shipowners who have chosen to install open loop scrubbers is presently the ban on the discharge of EGCS washwater in certain countries and ports. At the time of writing the following countries and ports have prohibitions in place:

China: From 1 January 2019, discharge of washwater from scrubbers is prohibited in the county’s inland emission control areas (ECAs), port water areas of coastal domestic ECAs and Bohai Bay waters. The document also states that a ban in the entire coastal domestic ECA will be announced in due course.

Singapore: According to the Maritime and Port Authority of Singapore (MPA), discharge is prohibited in Singapore port waters from 1 January 2020.

Fujairah: Has banned the discharge of washwater from 23 January 2019.

India: India seems to indicate that scrubber washwater discharges are allowed if the criteria set out in MEPC.259(68) are met. However, this is qualified with a requirement that local regulations should also be followed.

Abu Dhabi: Guidelines state that scrubber washwater can be discharged in port waters if free from pollutants whilst scrubber sludge should be discharged from the vessel to a licensed waste disposal contractor.

Belgium: Bans the discharge in ports and inland waters within 3nm of the coastline.

Germany: Discharge is not allowed in inland waterways and the Rhine.

Lithuania: The current position seems to be that discharge may not be allowed in port waters in the very near future.

Latvia: General position is that discharge is not allowed in territorial and port waters.

Waterford: An Irish authorities’ Notice stipulates that discharge of washwater is prohibited in waters under Dublin port jurisdiction.

Norway: The Norwegian Maritime Directorate (NMD) has proposed a ban on the use of scrubbers in the country’s heritage fjords, which extends to all types of scrubbers including closed loop and hybrid systems. Implementation is expected during the first half of 2019.

Hawaii: VGP rules allow for discharge of washwater subject to certain requirements being fulfilled.

Connecticut: There are specific conditions as part of the VGP requirements, prohibiting discharge of exhaust gas scrubber washwater into Connecticut waters.

California: CARB regulations do not permit the use of scrubbers, unless the vessel has an experimental or temporary research permit.

The question asked by many is why these countries and ports have now issued this ban as many believe that the results of studies conducted are inconclusive and until conclusive results are found bans should not be made. Irrespective of this belief, the fact remains that the ban in the mentioned countries and ports exists and therefore must be considered by shipowners when entering into charterparties, particularly when agreeing the trading areas of the vessel. Further thought must be given to the possibility of using low Sulphur fuel which complies with Marpol Annex VI Regulations in the areas that have banned the use of open loop scrubbers and appropriate charterparty clauses drafted to reflect the same.

If the agreed trading areas are restricted to those where the use of open loop scrubbers is permitted, then it is still advisable for shipowners to be aware that it is likely that the list of areas which have prohibited the use of open loop scrubbers may be extended. Shipowners may wish to insert clauses in their charterparty which unambiguously set the rights and obligations of shipowners and charterers were such a situation to arise.

(Source: Hellas HiLights March 2019)

How Can the 2020 Sulphur Cap Affect the Shipping Industry?

To support anyone preparing for the 2020 sulphur cap, and specifically shipowners and operators, LR has created and answered a set of the most frequently asked questions:

Is a Ship Implementation Plan (SIP) mandatory?

A SIP is not mandatory, but it is ship-specific and owners and operators should prepare one as it provides a chance for technical staff on board to review the ship’s fuel management procedures ahead of the new 0.50% Sulphur fuels. This will also assist technical staff to establish timelines for the ship when conducting operational, design, and system changes.

Should there be a comprehensive tank cleaning before 1 January 2020?

An assessment must be carried out on the base of each HFO bunker tank and a decision has to be made on the necessary course of action. There are little options being considered by the ship operators like:

- Flushing tanks with distillate ultra-low Sulphur fuels to flush the tanks, piping and fuel system components of high Sulphur fuel oil and sediment;

- Using one or more bunkerings of 0.50% fuels prior to the enforcement date;

- Use of a specialist additive dosed over various bunker loads before the first 0.50% is loaded to clean the tanks;

- A combination of the above.

When first using 0.50% fuels, LR suggests crewmembers to perform Sulphur sample checks from the system periodically to provide indications of the tank’s compliance condition.

What are the major quality concerns with 0.50% fuels?

Some of the key challenges and risks regarding the new 0.50% fuels are the following:

- Compatibility between fuels from different sources;

- Stability of the blends;

- Variability of certain physical parameters from different sources like viscosity and density;

- Compliance;

- Cold flow properties;

- Combustion performance of new blends.

In addition, a lack of preparation and planning will make these challenges worse. For this reason, crew training is crucial as they are on the frontline handling several technical challenges and ensuring resilient ship operations.

What is the update from ISO?

The work on the ISO/PAS 23263:2019 guidelines for fuel suppliers and users regarding marine fuel quality is going through a balloting process as per ISO procedures. Currently, it is expected that the ISO/PAS 23263 will be available by the end of September 2019.

The ISO working group’s main target is to address the 0.50% Sulphur fuels’ stability and compatibility. Informative Annexes also contain further guidance on the composition, general requirement, stability and comingling of fuels. Moreover, CIMAC WG7 for fuels will launch with a more detailed technical document regarding fuel stability and compatibility.

How are discussions shaping up at IMO?

It was noted that most discussions regard the consistent implementation of MARPOL Annex VI regulation 14.1.3. MEPC 74 launched guidelines for the implementation of the MARPOL Annex VI Regulation 14.1.3, and they will be released as a resolution in due course.

They will also address areas like key technical preparatory considerations, control measures by port states, control on fuel oil suppliers, and fuel oil non-availability, including a FONAR template and handling non-compliant fuel scenarios.

One of the big changes was the amendments to the Sulphur Verification Procedure (Appendix VI) to handle accuracy and precision of test results of both the current MARPOL sample, along with ‘in-use’ and ‘on-board’ sample. The MARPOL Annex VI sample test result would be considered as not meeting the requirement more than 0.50% after following the verification procedure. On the other hand, for the ‘in-use’ and ‘on-board’ samples the fuel will not have met the requirement if the test result is more than 0.53%.

Additionally, the guidelines for port state control aim to handle scenarios like when there is discrepancy between the Bunker Delivery Note (BDN) and independent ship results presenting non-compliant fuel has been loaded despite the declaration on the BDN stating otherwise. It was also recognised that there will be various scenarios to mitigate non-compliant fuel being on board, such as after applying a FONAR. Here, the guidance gives emphasis on the ship making every attempt to avoid putting itself into such a position.

What is more, the guidance also expects suppliers to ensure that fuel quality is acceptable for the receiving ship. MEPC 74 also worked to produce guidance in the event of failure of a single monitoring instrument and suggested measures if the scrubber fails to meet the provision of the guidelines.

Finally, LR mentioned that, in order to facilitate the consistent implementation, MEPC 73 agreed to ban the carriage of high Sulphur fuels that are over 0.50% on vessels not equipped with a scrubber, from 1 March 2020.

(Source: Safety4Sea)

Ten Tips to Detect a Phishing Email

With the uptick in ransomware infections that are often instigated through phishing emails, it’s crucial to take proactive measures to help protect yourself and your organization’s security.

Having a computer that is up to date and patched makes a big difference in reducing an organization’s overall risk of infection.

But being vigilant in detecting phishing emails and educating employees in your organization to also be proactive is a critical step in protection.

Here is a quick top ten list for how to spot and handle a phishing email.

(Source: Safety4Sea)

Preventing and Reducing Malaria Transmission

Recently, UK P&I Club Members reported two cases of death and two cases of serious illness (three months in hospital each) due to malaria. These cases arose despite the crew member being on medication to prevent the disease. It was later found that the crew members either did not have the correct medication, for the countries they were travelling to, or they were unsure about the correct dose they should be taking.

What is malaria?

Malaria is a life-threatening disease that is preventable and curable with early diagnosis and treatment. It is not contagious, but it is an infectious disease spread through infected female mosquitos, carrying one of several Malaria microorganisms.

Most malaria cases take place in sub-Saharan Africa, however, regions such as South-East Asia, Eastern Mediterranean, Western Pacific and the Americas are also at risk.

“In 2017, there were an estimated 219 million cases of malaria in 90 countries” and deaths caused by malaria reached 435,000” WHO Malaria Fact Sheet.

The dangers

If malaria is diagnosed and treated early, it is usually completely curable. However, if left untreated, it may lead to complications and, potentially, death. Some complications that can arise include: kidney failure, liver failure, acute respiratory distress, circulatory collapse, secondary infections and more.

The severity of the complications of malaria means that it is imperative for vessels travelling within, or close to, the endemic regions to carry prophylaxis (preventative treatment).

Signs and symptoms

Malaria usually has ‘flu-like’ symptoms, which include:

- High fever

- Chills

- Sweating

- Myalgia (muscle pain)

- Headaches

- Nausea

- Vomiting

- Jaundice

Prevention methods

- Carrying the correct medication for applicable geographic area on board in adequate quantities

- Mosquitoes are attracted by light and areas with stagnant water – care should be taken to ensure there is no stagnant water anywhere on a vessel, and that the amount of light is reduced, where safe to do so

- Ensure that no crew members sleep on deck

- Apply insecticides in cabins

- Use mosquito repellent sprays

- Avoid exposing skin

- Use mosquito nets that have been treated with an effective insecticide (on doors, windows, to sleep under, and over ventilation holes), especially at night

(Source: UK P&I Club, Information obtained from Med Solutions’ Malaria Overview and the World Health Organisation’s Malaria fact sheet.)